Optical fibre has become the cabling media of choice in new data centre deployments whilst existing facilities’ fiber continues to replace copper cables. It is because fibre offers greater flexibility, scalability, and bandwidth capabilities to support the ever-increasing volume of data. At the same time, the number of optical fibre links between switches, storage area networks (SANs) and equipment continues to grow to support new data centre architectures.

With the volume of fiber increasing and cabling designs changing, what does this means for protecting and routing this sensitive medium?

Keeping things clean and tidy

One of the biggest challenges that customers keep facing with fibre installations is the issue of cleanliness. Cleanliness refers to a dust and dirt-free installation environment for when the fiber is being terminated on site, but it also means a tidy and scrap-free data centre space so that cable and equipment can be installed properly.

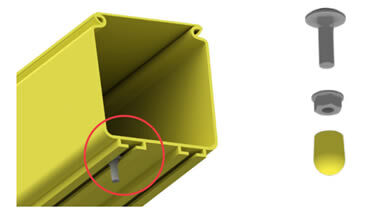

Traditional fibre routing systems without toolless joiners can be an issue here, especially when drilling takes place to connect duct to other duct or transition pieces like Ts and bends, or when connecting ducting to support hardware such as metal support brackets.

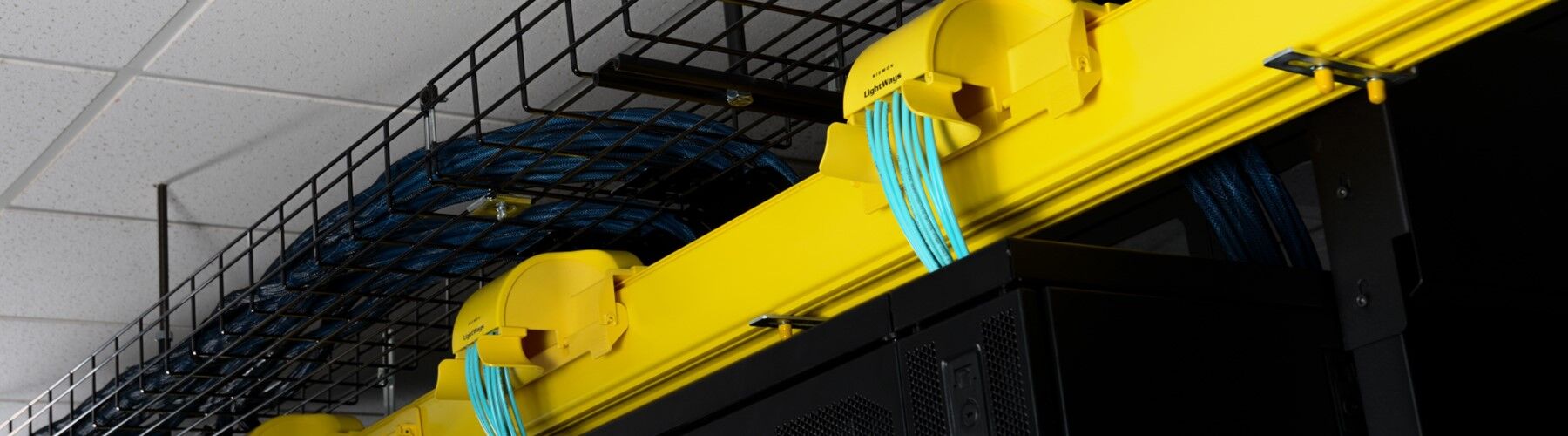

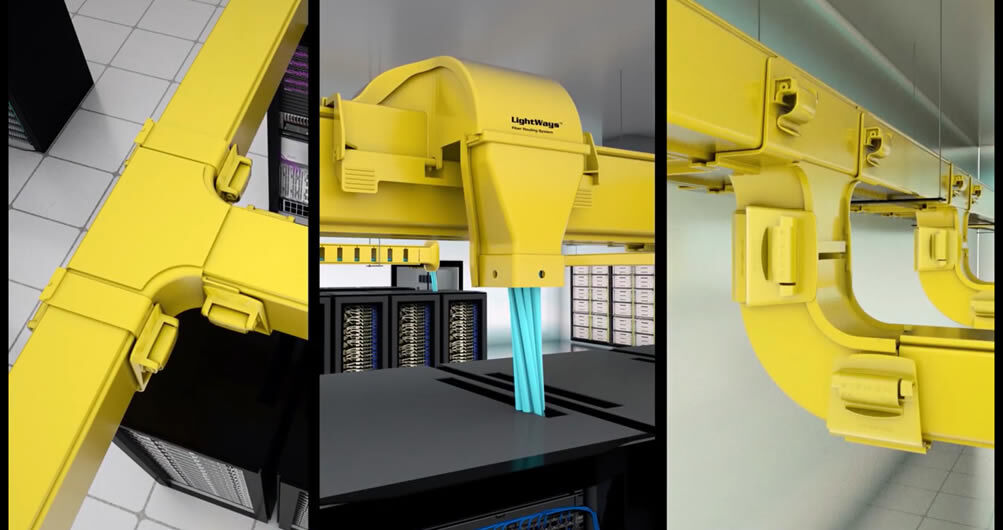

Plug-and-play containment systems such as Siemon’s LightWays® provide toolless joiners and ducting that accept mounting hardware without the need to drill to combine them together. This contributes to maintaining a cleaner data centre deployment.

Growing without concerns

Data centres are continually evolving, and the way critical network equipment is being connected keeps changing. With moves, adds and changes (MACS) occurring on a frequent basis, the cabling architecture keeps changing and other services (e.g., power) must be accommodated at times. When one dedicated and highly flexible pathway is utilised for the fibre cabling, cable re-routing becomes so much easier.

The same applies to the initial data centre deployment process or to capacity expansion as time goes by. A highly flexible and easy-to-assemble containment system will ensure that additional PODs or rows of cabinets can be added easily to enable a faster process.

When Siemon’s LightWays® is deployed, only a change in joiners, adapters and ducting is required to extend the fibre routing system for faster data centre growth. A broad range of different types of brackets provides greater flexibility in terms of where in the data centre the trays run.

Set for the future

Compliance levels in the data centre are generally reviewed every 12-18 months, meaning there is always a chance that the industry could turn around quickly and introduce new compliance regulations. In terms of material compliance and additional fire safety, cable containment systems soon may need to meet LSoH (low smoke zero halogen) requirements. With Siemon’s LightWays® you are ahead of the curve. Manufactured from halogen-free, flame-retardant UL94/V0 plastic it provides the highest level of compliance for any containment system so that the system you have in place will be future-proof from day one.

Peter Thickett

Innovation Leader, Siemon

Peter Thickett has worked for Siemon since 2008 and currently holds the post of Innovation Leader, where he oversees a range of solution-focused teams as well as strategic projects. During his time at Siemon, Peter’s held roles in Product Management, Product Development and Engineering and utilizes his background experience in the industry to drive innovation that helps Siemon to deliver truly innovative solutions that delight and empower its customers.